Oil Condition Monitoring

See your results

Log in to the Interlink portal using the details provided to view your results.

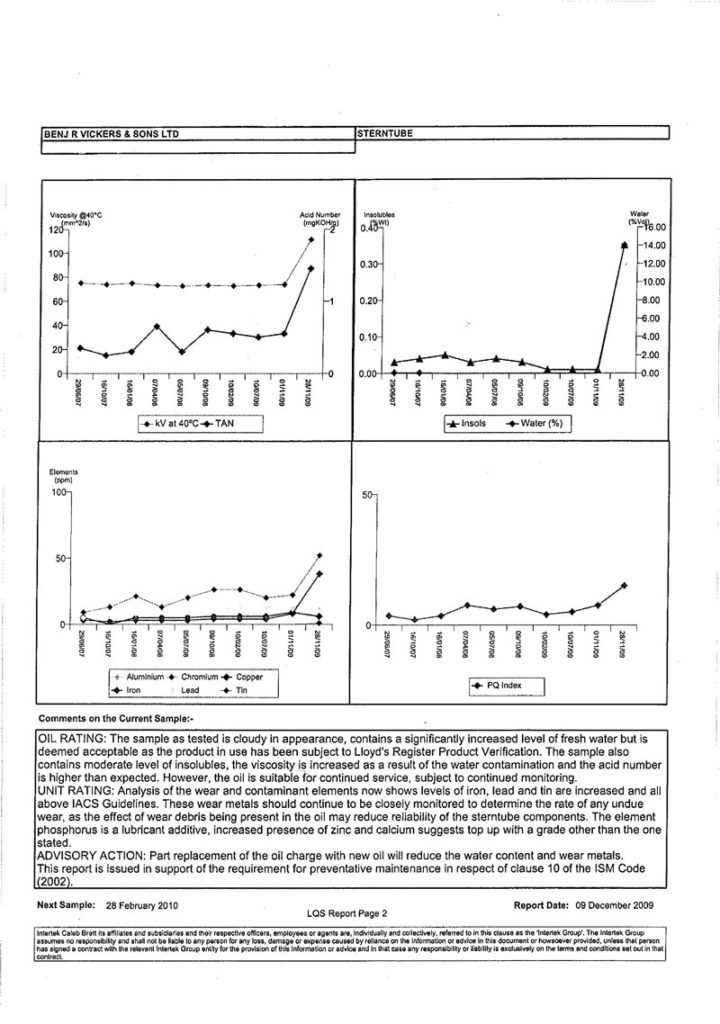

Our reports provide an assessment of both machinery performance and the lubricant condition

- Reduced maintenance costs

- Increased equipment reliability

- Enables proactive maintenance planning

- Improved safety and environmental protection

Oil analysis for marine lubricants

Our Condition Monitoring Service has been developed to allow owners and managers to have complete peace of mind with regard to the use of Vickers Oils’ lubricants in their vessels.

It is backed by a full service team to answer queries regarding test results and their interpretation. The service is offered based upon a tailored agreement covering each individual vessel participating in the service.

UNIQUE

This service is offered for sterntube, stabiliser, thruster and hydraulic applications in order to optimise lubricant performance.

A comprehensive database of results, drawn from over a decade of EAL analysis, allows us to expertly interpret the lubricant’s performance in your vessel.

The key feature of our service is that the resultant reports offer judgements on machinery health and not just lubricant condition. These judgements state, where appropriate, that the machinery is suitable for further service and does not require remedial action.

This would be the case even, for example, when HYDROX and HYDROX BIO samples contain up to 10 times more water than if conventional oil was in use.

SURVEY EXTENSIONS

Regular use of our Condition Monitoring Service can actually support applications for extension to the classification survey of a ship’s sterntube assembly. For example, the CM notation scheme operated by Lloyd’s Register can allow sterntube inspection to be deferred where sufficient documented evidence is available to support such a deferral. In such cases significant cost savings can be enjoyed by the client.

Reports can be made available to Classification Society Surveyors of whatever Class and will normally exceed their requirement regarding both the test suite and quality of reporting. Our service is compliant with the ISM Code ”Maintenance of the Ship and Equipment” and provides evidence of preventative maintenance in respect of Clause 10 of the ISM code.

To get started click here to register.

For more information please contact our Technical Service Department on +44 (0)113 386 7654 or Email: ocm@vickers-oil.com

Samples must always be taken from the same point in the system when the oil is circulating at normal operating temperature. Think safety when sampling hot or potentially hot systems. Avoid sampling from filter or cooler drain cocks and sump tanks, as these may not be representative of this system.

Wipe clean around sampling point and drain off a quantity of oil to purge sampling cock and pipe.

Draw off oil into a Vickers Oils sample bottle. For full analysis a FULL bottle is required (bottles provided).

Immediately affix screw lid tightly and check to make sure that the bottle does not leak.

Select the appropriate address label from the labels provided and attach to the mailing tube. Insert sample bottle upside down.

Complete ALL the information on the green ‘Routine Analysis Data’ form provided and insert in mailing tube with sample providing one form per sample.

Place the end cap over the tube and push firmly down in the centre ensuring it is firmly secure.

CONTACT AND FLASH POINT LABELS SHOULD BE PLACED ON OUTER MOST PACKAGING FOR VIEWING BY CUSTOMS.

Hand the sample(s) to the agent with instructions for immediate despatch. Landing station details can be found here.

DEPENDING ON SAILING PATTERNS PLEASE CHOOSE ONE OF THE FOLLOWING LANDING STATIONS