Wire Rope Lubricants and Grease

Choosing the right lubricant

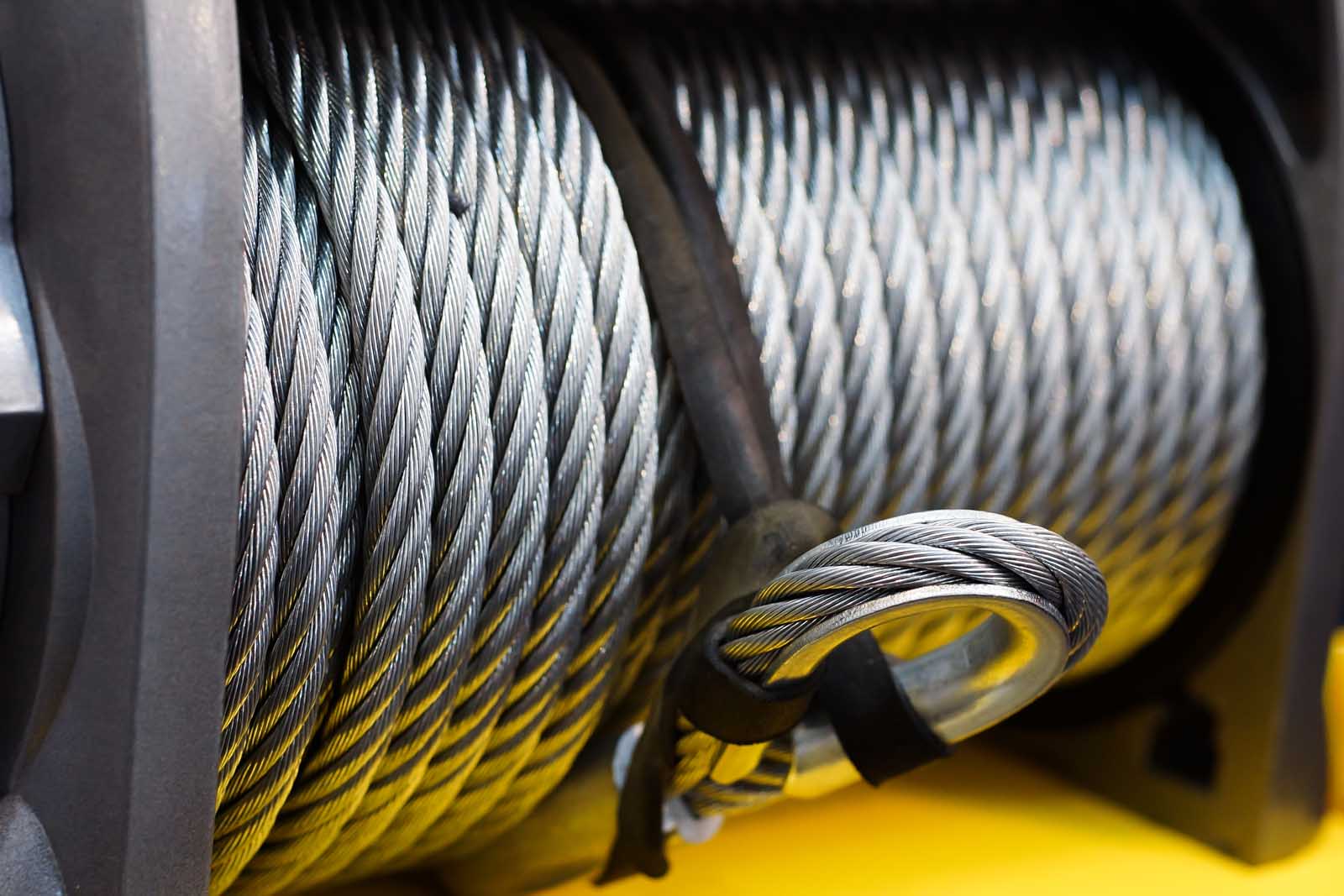

Using the correct lubricant with the appropriate application method can not only maximise the wire rope life but can also eliminate costly replacements and improve safety.

Two key factors that influence the life of the wire rope are resistance to wear and prevention of corrosion.

The correct type and quantity of lubricant will protect the wire rope from degradation, wear, and corrosion.

The fluidity of the lubricants helps to ensure that the rope strands are well lubricated, reducing internal wear caused by the metal-to-metal contact occurring when the wires slide or bend around a drum or sheave.

The Wire Rope Lubricants and Grease range prevent corrosion by displacing moisture and forming a thin barrier of continuous lubricant film protecting against the elements.

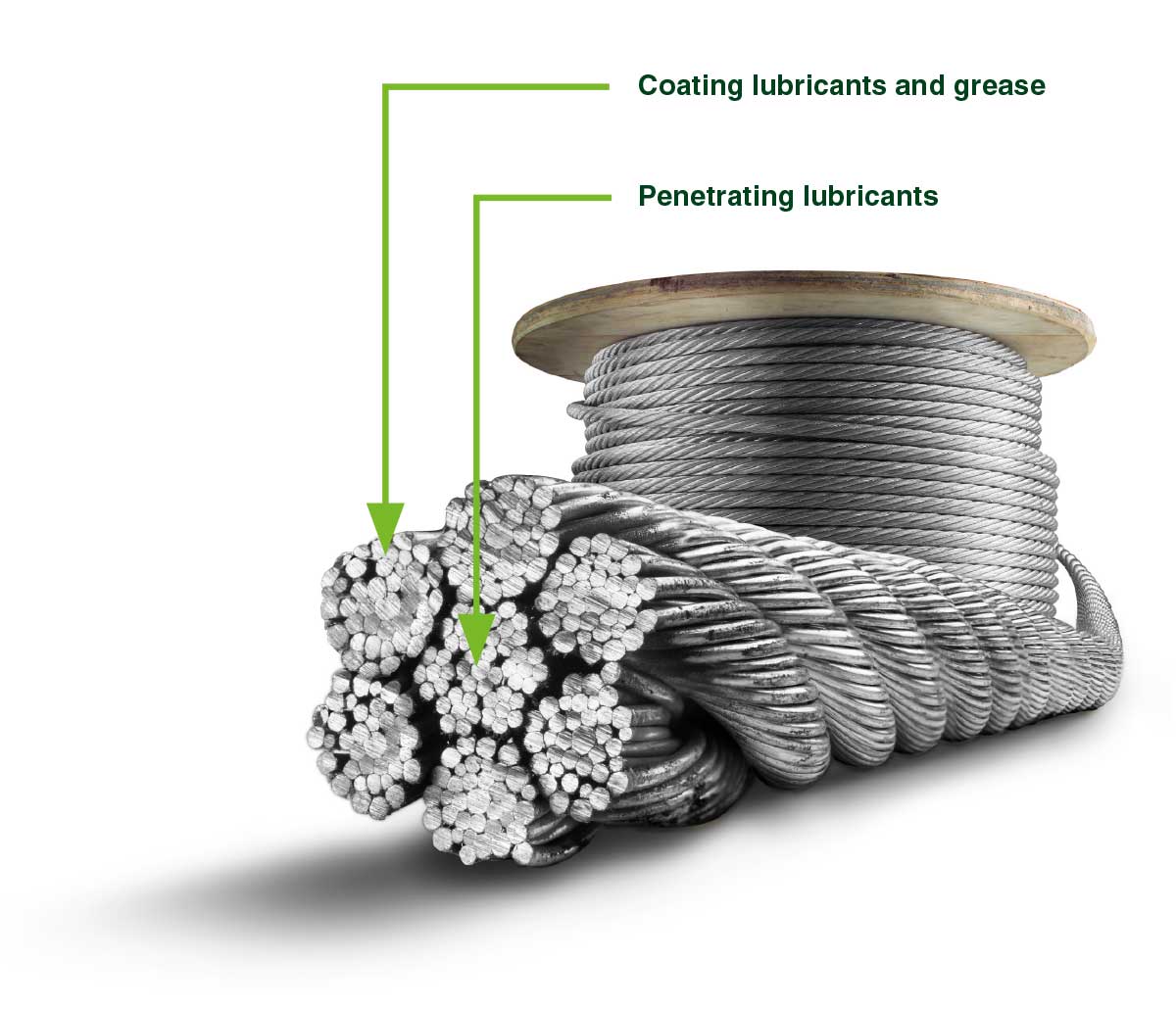

Types of lubricants for Protecting Wire Rope

- Penetrating lubricants contain a solvent component that facilitates penetration of the lubricant into the core of the wire rope.

The solvent then evaporates leaving an oil film that protects and lubricates each strand. - As wire ropes may fail from the inside, it is critical to ensure the centre core receives sufficient lubricant.

Coating lubricants and greases penetrate slightly and seal the outside of the cable from moisture, reducing wear, rust, and corrosion.

Vickers Oils Wire rope lubricants and grease have been designed specifically to meet and exceed a variety of requirements across a wide range of applications and operating environments

Explore our range of Innovative and OEM Approved Lubricants

Trusted for Generations

An award-winning range of EALs (Environmentally Acceptable Lubricants)

Regional stock points

in over 40 locations

Ability and infrastructure to respond quickly to urgent requirements

Service & Support

30% of our workforce are employed in the technical team, focusing on Quality Control, R&D, OEM liaison and Technical Service allowing us to provide one-on-one dedicated customer support by our team of highly qualified experts.